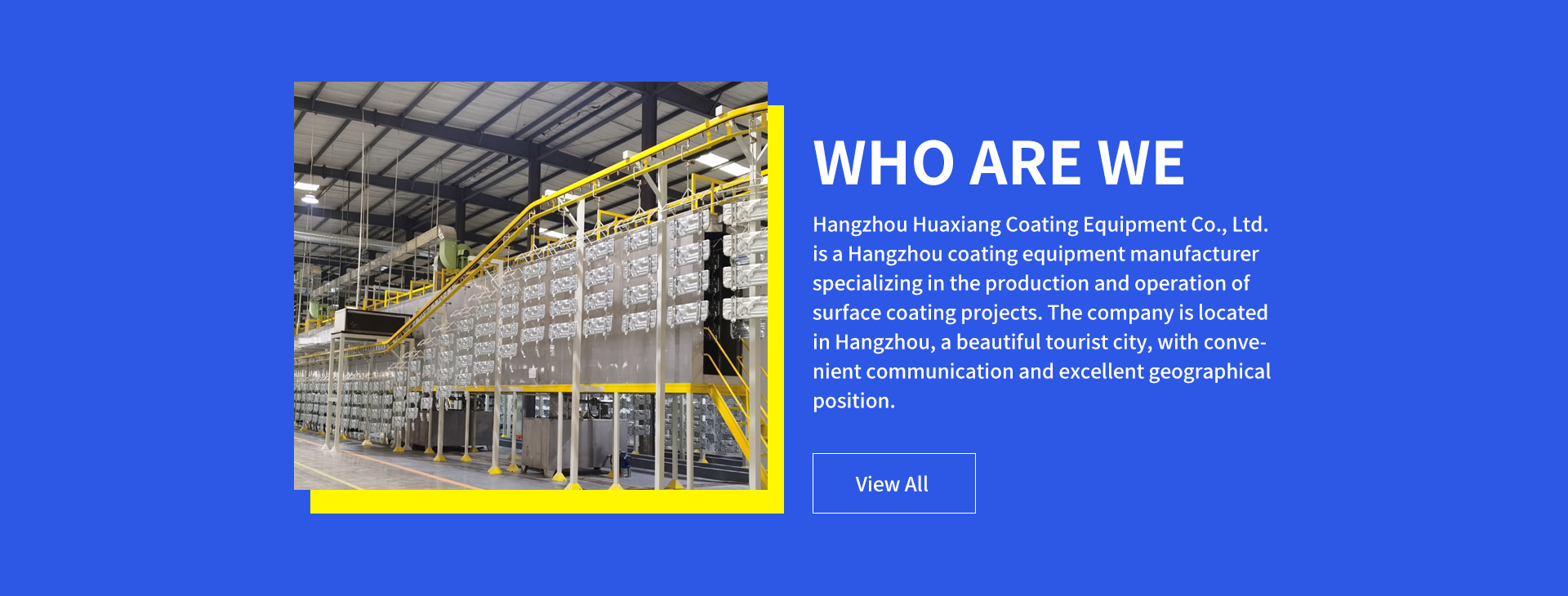

1. Introduction and Structure of Automatic Powder Coating Line Factories

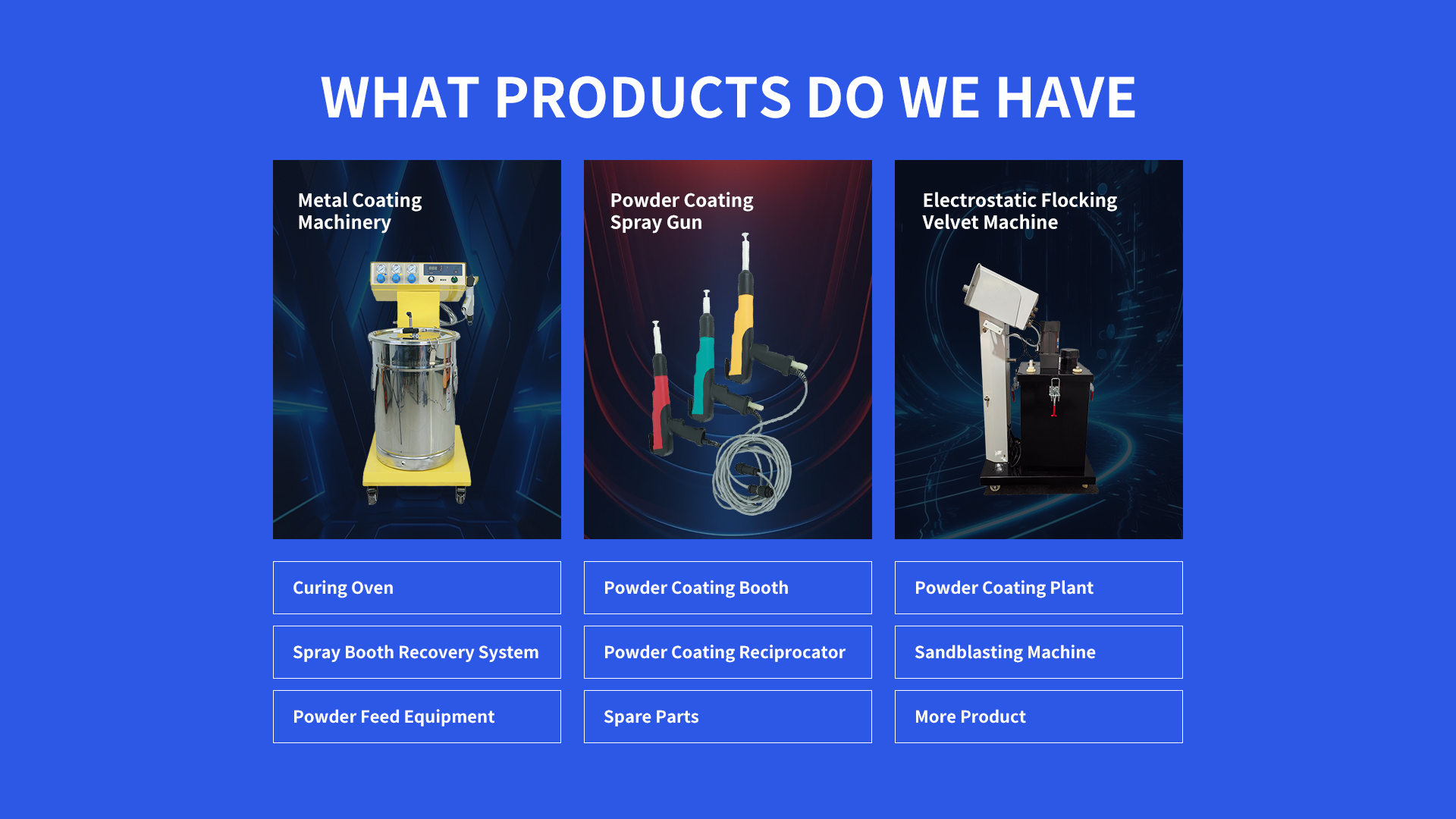

Automatic Powder Coating Line Factories specialize in manufacturing advanced systems for applying powder coatings to metal surfaces. These systems typically include a pretreatment unit (cleaning, degreasing), electrostatic spray booth, curing oven, conveyor system, and powder recovery unit. Factories often design modular and customizable solutions to meet diverse industrial needs.

2. Applications of Automatic Powder Coating Line Factories

These factories serve industries such as automotive, aerospace, construction, and consumer electronics. Their systems are used to coat car parts, aircraft components, architectural aluminum, and household appliances. The durability and eco-friendliness of powder coatings make them ideal for high-performance applications.

3. Pricing of Automatic Powder Coating Line Factories

The cost of systems from these factories ranges from 50,000forbasicmodelstoover1 million for fully automated, high-capacity lines. Pricing depends on factors like production capacity, automation level, and customization. Factories may offer financing or leasing options to accommodate budget constraints.

4. Proper Usage of Automatic Powder Coating Line Factories

To ensure optimal performance, operators should pre-treat surfaces, calibrate electrostatic guns, maintain consistent conveyor speeds, and monitor curing temperatures. Regular maintenance, such as cleaning spray guns and replacing filters, is essential for long-term efficiency.

5. How to Choose the Right Automatic Powder Coating Line Factory

When selecting a factory, consider their experience, customization capabilities, and after-sales support. Evaluate the energy efficiency, powder recovery rates, and automation levels of their systems. Reputable factories often provide case studies or client testimonials to demonstrate reliability.

6. Safety Precautions for Automatic Powder Coating Line Factories

Factories must ensure their systems comply with safety standards. Key precautions include proper grounding to prevent electrostatic discharge, explosion-proof equipment in spray booths, and adequate ventilation to minimize powder inhalation. Regular safety audits and operator training are essential.

7. Design Rationality of Automatic Powder Coating Line Factories

Leading factories focus on energy-efficient designs, such as hybrid curing ovens and heat recovery systems. Modular designs allow for scalability, while IoT-enabled monitoring ensures real-time performance optimization. These features reduce operational costs and improve ROI for businesses.

8. Q&A on Automatic Powder Coating Line Factories

Q: What industries benefit most from these systems?

A: Automotive, construction, and electronics industries.

Q: How to ensure coating uniformity?

A: Use calibrated electrostatic guns and consistent conveyor speeds.

Q: Can factories customize systems for small workshops?

A: Yes, many offer compact, semi-automatic solutions.

Q: What maintenance is required?

A: Regular cleaning of guns and filters, plus system inspections.

Q: Are these systems eco-friendly?

A: Yes, they use solvent-free powders and efficient recovery systems.

Disclaimer: Enhance your coating process with advanced electrostatic powder coating machines, precision powder coating spray guns, comprehensive powder coating systems, and efficient powder coating lines from Hangzhou Huaxiang Coating Equipment Co., Ltd. Designed for reliability and high-quality finishes, our solutions meet all your industrial powder coating machine needs. Contact us at sale3@cncolourspray.com